About Us

The advent of the internet has brought about a wealth of resources to people interested in almost any field imaginable. Unfortunately, as someone who maintains and repairs drawbridges, I found very few places where I could ask questions or learn new information relevant to my industry. What I was looking for was drawbridge related news, articles, resources and links of interest.

Drawbridge Specific was born out of that frustration. With a smattering of basic information and data, we offer helpful links to industry related websites, highlights of drawbridges in the news, and blog posts on wide ranging topics all relevant to the world of drawbridges.

Stop by often to check out the topics, read a new story and discover a new link. Always feel free to post a comment or ask a question. And if you want to share a story that may be of interest concerning drawbridges, please contact us and let us know. We would welcome working with you to post a guest article.

New! Ask A Question Section

Have a question about drawbridge maintenance, repair or just a general question concerning drawbridges? Send your questions to: questions@drawbridgespecific.com and I’ll give you the best answer I’ve got and post them here. Since most of the inquiries we’ve received have been about drawbridges in general, we’ll start with some of these. Check back to see more answers as they post!

Question – J. M. asks – If a bridge gets stuck open, how do workers even get to the bridge to repair it?

Answer – Hey J. M.,

The short answer is: very carefully! Each bridge has its own unique setup, so repair crews must learn the safest way to approach each one while minimizing the risk of traffic accidents.

For example, on my vertical lift bridge, if I need to access the control room, I have to approach from a specific side of the river and turn onto the lanes normally used for outgoing traffic. This route leads directly to the control house, but before parking, I always make sure to turn back into the direction of intended travel to maintain proper traffic flow.

On a bascule bridge that leads to a popular beach community, the situation is a bit different. Sometimes, I have to drive nearly a mile in the opposite direction of traffic because the other side is completely gridlocked. In these cases, I use my strobe lights and flash my headlights, proceeding very cautiously. Fortunately, traffic is usually light on my side since most vehicles are stuck on the island.

Every bridge presents its own challenges, but rest assured that maintenance and repair crews always take every possible precaution to access the bridge safely and avoid creating additional traffic problems. Thanks for your question!

History Of Drawbridges

Some basic background information to get you started.

Types Of Drawbridges

The Principles Of A Drawbridge

Most drawbridges today operate on the exact same principles as the ones from 100 years ago.

Drawbridges In The News

Every week we highlight a news story featuring a notable drawbridge incident. While some of these are fairly old, they all illustrate the incredible things that can happen at any time and hopefully provide a warning we can heed or a lesson we can learn.

Many questions when drawbridges are to be replaced

This story shows that beyond the normal questions involved when replacement of a drawbridge is contemplated, sometimes issues arise that many would never even consider. Such as whether to turn the old bridge into a historic pedestrian park, for example.

Drawbridge Related Links

This week's link of interest

Galco is an amazing source for many things drawbridge related. I have used them for resolvers, encoders and VFD keypads just to name a few things. They also provide repair services for many control cards. Check them out for yourself.

Blog Posts

Every week we try to post a drawbridge related blog post, article or story. To see past postings, visit our Blog Archive. And as always, feel free to contact us for questions or comments.

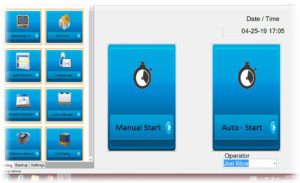

BridgeTender Software

Vessel logs are hard to take, hard to read and hard to store. Bring your log taking into the 21st century with the new BridgeTender software. Store information in a searchable database and take advantage of real time notifications of bridge openings via X! (formerly Twitter)